FAQs

Frequently Asked Questions

Yes, bollard barriers are designed to withstand vehicle collisions, providing robust protection in various environments. The effectiveness of a bollard barrier depends on its construction materials and design specifications. Crash-rated bollards are engineered to absorb impact and prevent unauthorized vehicle access, making them ideal for high-risk areas. They are often made from materials like steel or concrete, ensuring durability and strength. Properly installed bollard barriers can significantly reduce the risk of damage to property and enhance pedestrian safety by acting as effective physical barriers against potential collisions.

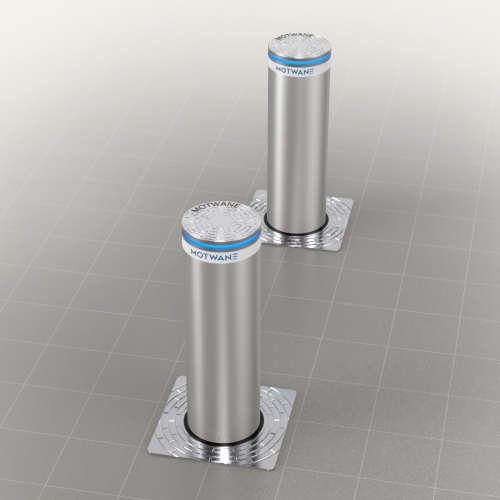

SS bollards, or stainless-steel bollards, are durable and corrosion-resistant barriers commonly used in various applications for security and traffic control.

Crash Rated bollard

are specifically designed to withstand vehicle impacts, providing enhanced safety in sensitive areas. These bollards stainless meet specific crash rated bollard specifications to ensure they can effectively stop or deflect vehicles during a collision. Crash protection bollards are often crash tested bollards that have undergone rigorous testing to validate their strength. Additionally, anti ram and anti ram raid bollards are engineered to prevent unauthorized vehicle entry and protect buildings from potential threats. Anti crash bollards serve a similar purpose, ensuring that both pedestrians and property remain safe from vehicle-related incidents.

The typical height of bollards for parking usually ranges from 36 to 48 inches, depending on their intended use. Bollard vehicle barriers intended for parking are typically taller to enhance visibility and deter vehicles from encroaching on pedestrian areas. Heavy duty bollards are specifically built to withstand impacts, making them an excellent choice for high-traffic areas. Vehicle bollards can be fixed or movable, with options like motorized bollards that automatically rise and lower for controlled access. Additionally, telescopic bollards provide versatility, allowing users to adjust the height based on specific parking needs and accessibility requirements.

Yes, rising bollards are specifically engineered to withstand a range of weather conditions. Retractable security bollards, including retractable bollards automatic, are typically constructed from durable materials like stainless steel or galvanized metal, which protect them from corrosion and wear. Automatic retractable bollards are engineered to operate reliably in harsh environments, with weatherproof mechanisms that prevent damage from rain, snow, or extreme temperatures. Automatic hydraulic bollards also feature seals and protective coatings to enhance their resistance to moisture and dirt, ensuring long-lasting performance and minimal maintenance throughout the year.

Bollards on the road significantly enhance pedestrian safety by creating physical barriers that control vehicle access and traffic flow. Hydraulic bollards can be installed to restrict vehicles from entering pedestrian zones, ensuring safe pathways for walkers. The rising bollards cost can vary based on design and functionality, but they provide crucial protection in busy areas. Automatic retractable bollards allow for controlled access, enabling vehicles to enter when necessary while keeping pedestrians safe. Understanding the automatic bollards cost helps municipalities and businesses invest in effective solutions that prioritize pedestrian safety while considering budget constraints. Additionally, Motwane Security offers customization in size, design, or color to meet specific requirements, ensuring that the bollards seamlessly integrate into any environment.

Bollard traffic systems come in three primary types: fixed, removable, and retractable. Fixed bollards provide permanent barriers to control vehicle access and enhance security in specific areas. Removable bollards offer flexibility, allowing for easy installation and removal when access is needed. Retractable bollards can be raised or lowered automatically, enabling dynamic traffic control while providing security when necessary. Each type serves different purposes, catering to various applications such as pedestrian zones, parking areas, and security-sensitive locations.

High Visibility Motorized (HVM) bollards are installed for traffic control by following a systematic process. First, the installation site is assessed to determine the optimal placement for effective access management. After marking the locations, excavation is done to create a suitable foundation. The HVM bollards are then securely mounted using a robust base, ensuring stability and durability. Wiring is connected for automatic operation, and the system is tested to ensure proper functionality. Finally, the area is restored, ensuring the bollards effectively control traffic while enhancing safety.

K Rated bollards are security barriers engineered to endure vehicle collisions and safeguard essential infrastructures. These K Rated bollards come in different ratings, including K4 rated bollards, which can stop a vehicle weighing 4,000 pounds traveling at 40 miles per hour. K8 rated bollards are designed for slightly heavier impacts, while K12 crash rated bollards can resist impacts from vehicles up to 15,000 pounds at the same speed. The K4 crash rating is often applied to K4 rated fences to ensure comprehensive protection. Understanding the K12 rated bollards and their specifications, including the K12 bollard rating, helps organizations choose the right barriers for security needs. Similarly, K12 rated fences provide enhanced safety for high-risk areas.

K4, K8, and K12 bollards are typically made from durable materials designed to withstand high-impact collisions. These bollards are commonly constructed from heavy-duty steel, ensuring maximum strength and resilience. Some models may use stainless steel for added corrosion resistance, making them suitable for various environmental conditions. Additionally, certain bollards feature reinforced concrete to enhance their impact resistance. The choice of materials ensures that K4, K8, and K12 bollards effectively protect critical infrastructures while maintaining their structural integrity over time.